- NO63, XinTai Road, XinMaLian, DaLang Town, Dongguan City, Guangdong province

- info@baofengmachine.com

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

BAOFENG BF-2016L Double Column Machining Center

The X/Y axis adopts heavy load roller linear guideway, Z-axis square guideway,roller guideway optional.Integrated casting structure, increase the cutting rigidity and precision stability of the machine.Large span inverted L type Y-axis guideway structure, increase the Y-axis structure rigidity and Z-axis cutting rigidity. High-quality resin sand casting, fixed gantry type frame structure, Z-axis adopts laminated slideway system

Description:

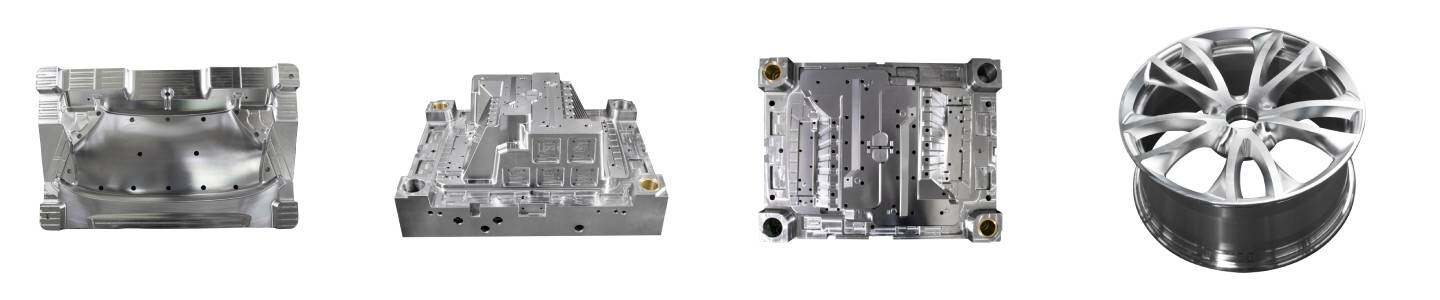

Double column machining center is mainly used for the processing of large boxes, complex surface molds, large-shaped parts.

Heavy Duty CNC Gantry Type Milling Machining Center

This kind of BF-2016L CNC is Universal Fixed Beam CNC Gantry Type Milling Machining Center for Highly Productive and Flexible Performance.

Such High Precision Double Column CNC Gantry Type Machining Center with Solid Work Table 2200 X 1300 mm and Maximum

Load Capacity 5000 KGS which is has ISO9001 factory with CE Safety Certification.

Universal Fixed Beam Double-Column CNC Gantry Type Milling Machining Center for Heavy Cutting, High-Volume Work-pieces

Features

X/Y axis adopts heavy load roller linear guideway, Z-axis square guideway, roller guideway optional.

Integrated casting structure, increase the cutting rigidity and precision stability of the machine.

Large span inverted L type Y-axis guideway structure, increase the Y-axis structure rigidity and Z-axis cutting rigidity.

High-quality resin sand casting, fixed gantry type frame structure, Z-axis adopts laminated slideway system,

which is suitable for high rigidity and precision parts processing.

Spindle, guideway, bearing, and other key parts are all imported from famous brand

in Japan, Germany, or Taiwan to ensure high precision, high quality, and high stability.

Modular design, which made many different types of optimized models, that satisfy the different customer processing needs and fast delivery requirements.

Special model

- Equipped with Germany ZF Gearbox or Taiwan gear type spindle box to realize strong cutting.

- Equipped with Taiwan right angle milling head to realize simple horizontal machining requirements.

- Equipped with Taiwan universal milling head to realize multiple angle machining requirements.

- Equipped with automatic pentahedron milling head to realize multiple dimension high precision machining.

Specification

| TRAVEL | |

|---|---|

| X/Y/Z axis travel | 2200x1600x800mm |

| Spindle nose to table | 250-1050mm |

| Spindle center to column | 1630mm |

| Positioning accuracy | ±0.005/300mm |

| Repeated positioning | ±0.003/300mm |

| Spindle | |

| Spindle taper | BT50 |

| Spindle transmission | belt drive |

| Spindle speed | 6000 rpm/min |

| Controller | |

| CNC control | Fanuc 0i-MF |

| Spindle motor | 15/18.5 kW |

| X/Y/Z motor | 4.5/4.5/4.5kw |

| Table | |

| Table size ( W x L ) | 2000x1300mm |

| T slot | 6-22x190mm |

| Table load | 5000kg |

| Feed | |

| X/Y/Z rapid feed rate | 15/15/12m/min |

| X/Y/Z linear guideway | box guideway |

| X/Y/Z ball screw | C3 |

| MACHINE DIMENSION | |

| Dimension | 6400/4800/4200mm |

| Weight | 21000kg |

Main parts list:

| Item | Brand |

|---|---|

| Spindle | Baofeng |

| Spindle bearing | Japan-NSK |

| Ball screw | Taiwan-Hiwin/PMI |

| Linear guideway | Taiwan-Hiwin/PMI |

| Pneumatic parts | Japan-Mitsubishi |

Optional configuration:

- SIEMENS/FANUC/Mitsubishi CNC Controller

- 24T/30T Arm type tool magazine

- Coolant through spindle

- 4th/5th axes rotary table

- Chip conveyor

- Tool setter

- Oil mist collector

FAQ

Q1. What's the MOQ?

A: 1 set.

Q2. What's your lead time?

A: It depends on the customer's requirement and quantity.

Q3. What's the payment term?

A: T/T or L/C. Negoiated.

Q4. How do you guarantee the quality of your products?

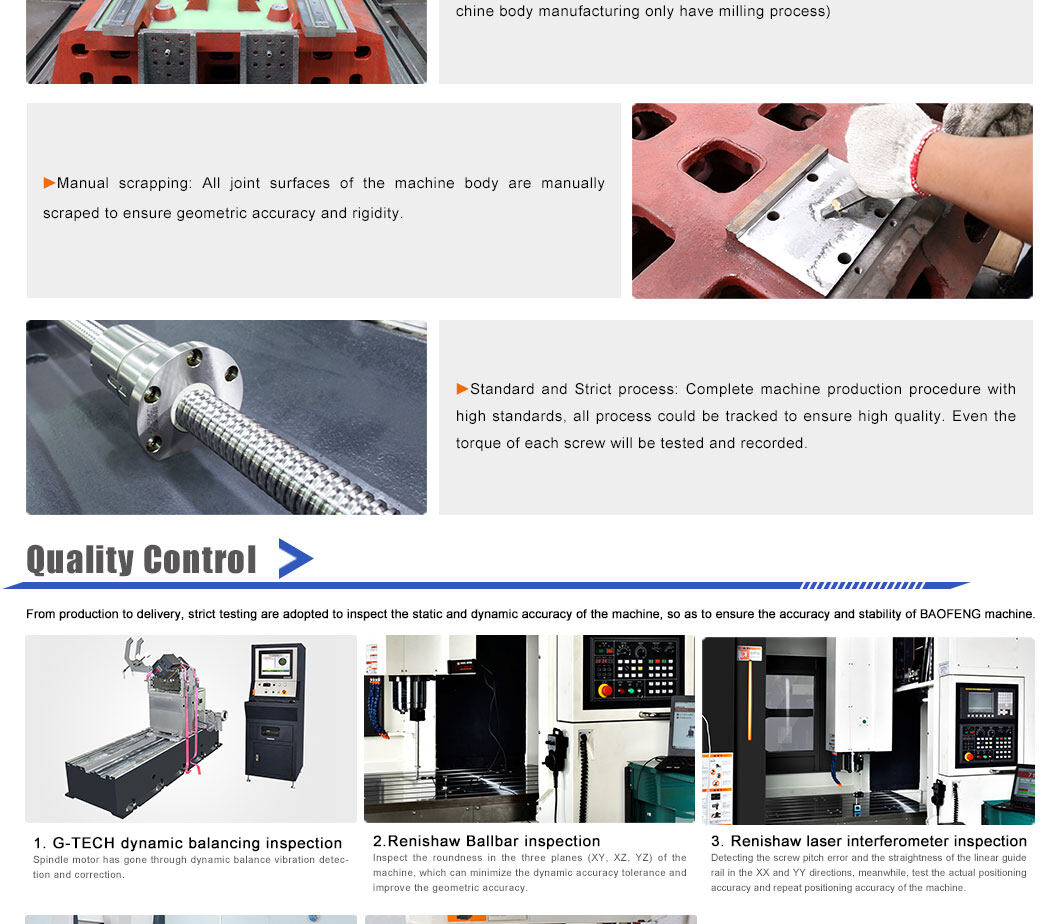

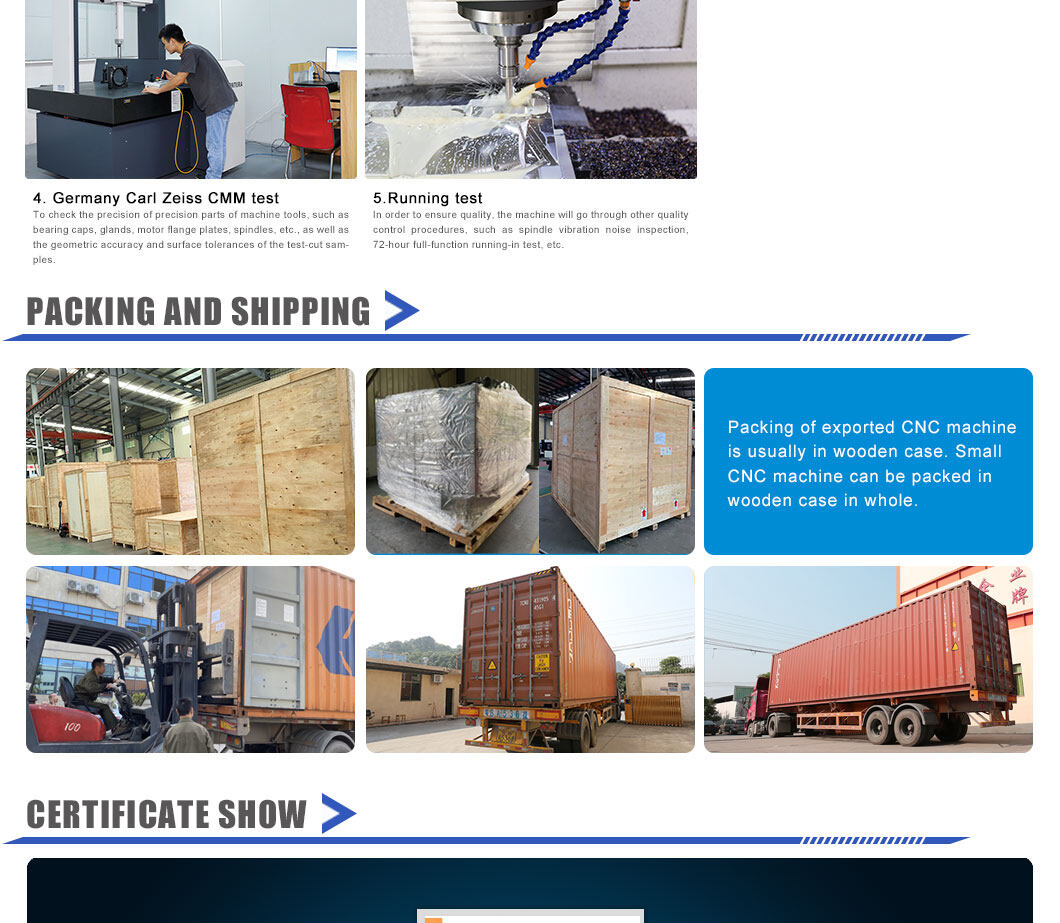

A: Each machine tests with professional Germany Inspection equipment before shipping.

Q5. Where is your factory located?

A: We have three factories in China. The biggest one is located in Huangshi City, Hubei Province;

the other two are located in Dongguan City, Guangdong Province.